Nine Questions and Answers on Industrial Vibration Sensor Selection Selecting an accelerometer for predictive maintenance is a daunting task, even for experienced engineers. The process can usually be filtered down to nine questions.

Find the answers to the following nine questions and, based on your actual application, you will be able to find the best vibration monitoring solution.

Question 1: What do you want to measure? This may seem obvious, but think twice. What is it that you really want to measure? In other words, what do you want to do? What do you hope to get? What do you plan to do with the data? Accelerometers can monitor vibration and provide raw vibration data, while vibration transmitters provide root mean square (RMS) values. Analyzing raw vibration data is useful because it contains all the information of the vibration signal, the true peak amplitude and vibration frequency. Because the RMS total or peak value is a continuous 4-20 mA signal, it is very useful in control systems such as PLCs, DCSs, SCADA systems, and PI systems. Some applications use both signals at the same time. By determining the various signals required for your application, you can narrow your search significantly. Also, are you measuring vibration as acceleration or velocity or displacement? Have you considered that some industrial sensors can output both vibration and temperature? Finally, some field applications, such as vertical pumps, are better at monitoring vibration on more than one axis. Does your field application require single-axis, dual-axis, or tri-axis measurement?

Question 2: What is the amplitude? The amplitude or range of the vibration being measured determines which range of sensor to use. Typical accelerometer sensitivities are 100 mV/g for standard applications (50g range) and 500 mV/g for low frequency or low amplitude applications (10g range). 4-20 mA transmitters for general industrial applications typically use a range of 0-1 in/s or 0-2in/s.

Question 3: What is the frequency of vibration? Physical structures and dynamic systems react differently to different excitation frequencies. Vibration sensors are no different. Piezoelectric materials act like high pass filters by nature, so even good piezoelectric sensors have a low frequency limit of about 0.2 Hz. The sensor, as a single degree of freedom dynamic system, has a natural resonant frequency. The signal is greatly amplified at the natural resonant frequency, resulting in a significant change in sensitivity and possibly over-range. Most industrial accelerometers have single or dual RC filters to cancel the excitation of the resonant frequency. It is critical to select a sensor with a usable frequency range that includes the frequencies of interest.

Question 4: What is the ambient temperature? For ICP accelerometers and 4-20mA transmitters, very high ambient temperatures pose a threat to the internal electronics. Charge mode accelerometers can be used in very high ambient temperatures and do not have internal electronics, but instead use a remote charge amplifier. Charge mode accelerometers come with an integral hard wire cable and can be used in applications where the temperature exceeds 260°C, such as gas turbine vibration monitoring.

Question 5: Will it be submerged in liquid? Industrial accelerometers with integral polyurethane cables can be submerged in liquid. For high pressure applications, the sensor is pressure tested for one hour. Fully submerged applications require an integral cable. Integral cables are also required in applications where spraying but not full submersion occurs, such as machine tool cutting fluids.

Question 6: Will the sensor be exposed to potentially harmful chemicals or debris? Industrial accelerometers can be constructed using corrosion and chemical resistant stainless steel. In environments with harmful chemicals, consider using a PTFE corrosion resistant connecting cable. It is strongly recommended to check the chemical compatibility chart for any suspected chemicals. For environments where there may be contact with cutting chips, integral armored cables provide good protection.

Question 7: Do you need a push-out, offset, or small link? Terminal sensors need to be installed in the available space of the equipment. The shape of the sensor has little effect on its performance, but it needs to be considered for safe installation and maintenance operations in the field. Small accelerometers with locking nut design can be fixed in any direction, but it is convenient when equipped with an integral cable.

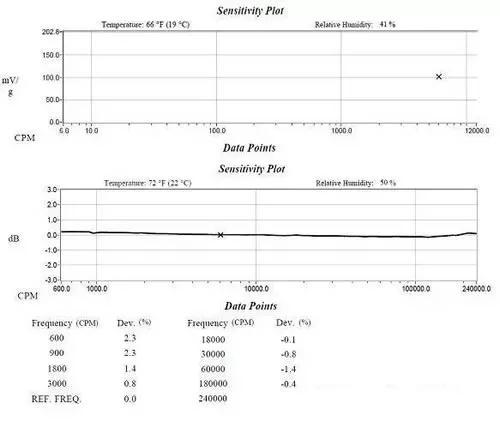

Question 8: Are you using a high-precision or low-cost sensor? There are two main differences between low-cost and high-precision accelerometers. First, precision units are usually fully calibrated, which means that the sensitivity response is measured and plotted over the available frequency range. Low-cost accelerometers are single-point calibrated, with sensitivity measurements taken at only one frequency. Second, high-precision accelerometers have tight tolerances on certain specifications such as sensitivity and frequency range.

For example, a high-precision accelerometer has a nominal sensitivity of 100 mV/g±5% (95 mV/g to 105mV/g), while a low-cost accelerometer has a nominal sensitivity of 100mV/g±10% (90 mV/g to 110mV/g). Customers can set the sensor's calibrated sensitivity in the data acquisition system so that the low-cost sensor can also provide accurate and repeatable data. As for frequency, high-precision accelerometers usually have a deviation of 5%, while low-cost sensors can provide a frequency range of 3 dB. Even so, a low-cost sensor can provide excellent frequency response.

Question 9: Do you require special approvals? Accelerometers and 4-20 mA transmitters are available with CSA and ATEX approvals for use in hazardous areas. Compare the sensor's approvals to make sure it meets your needs. The answers to these nine questions can greatly narrow your search for a solution that meets your application. Keep in mind that the answers combined may be mutually exclusive, meaning that solutions that meet every standard may not exist. For example, a specific model for use in hazardous areas may not have ATEX approval. Additionally, a specialized field application may have other considerations.