Contact Us

- Building B, No. 17, Zijing Road, Pingxi, Pingdi Street, Longgang District, Shenzhen

- 934728633@qq.com

- +0755-29698036

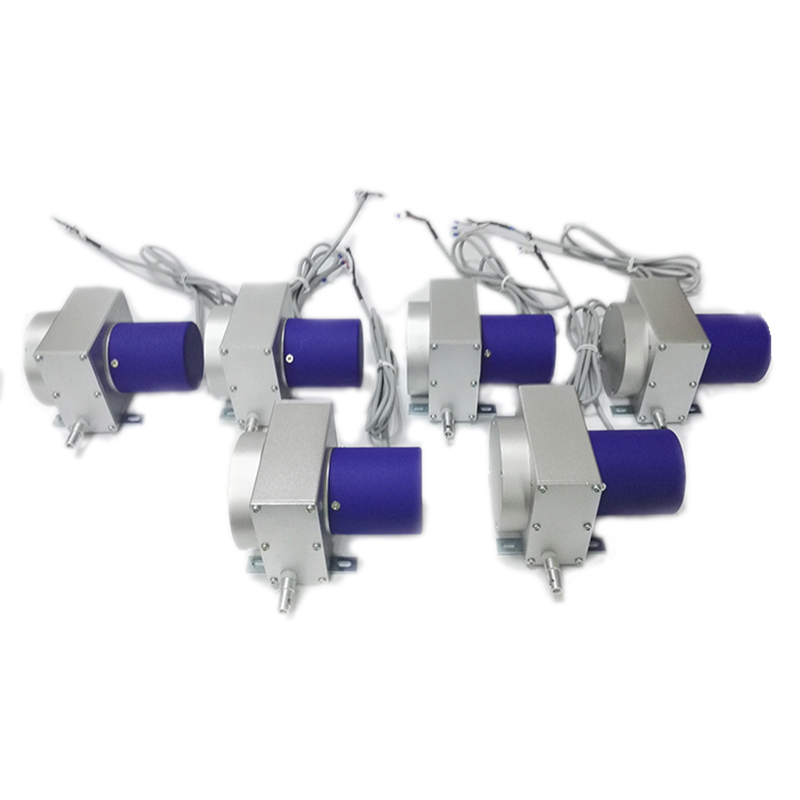

BWLS-S Pull Rope Series

| S type base number | Maximum effective stroke 2250mm |

| Linear accuracy | Linear accuracy: (general type) 0.25%FS; (precision type) 0.05%~0.08%FS |

| Repeat accuracy | Repeat accuracy: 0.01%FS~0.005%FS |

| Product type | Current type (4~20mA ; or 20~4mA); Voltage type (0~10Vdc; or 10~0Vdc) Resistance type (0~5kΩ; or 0~10 kΩ); Pulse type ( Generally 3600~5000 ppr, incremental) |

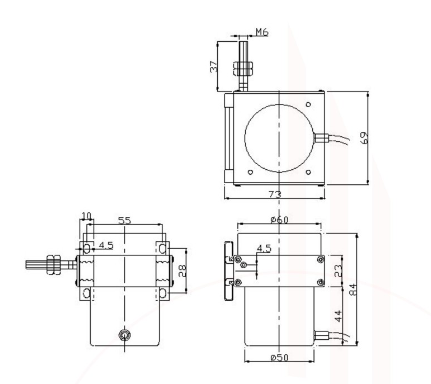

| Fixing screws | M4mm; Installation method: Bracket (two) |

| Effective life | 5 million reciprocating strokes; Protection level: IP67 |

| Power supply voltage | 24VDC (pulse type power supply voltage: 5~24VDC) |

| Mounting bracket hole distance | 28± 0.5mm |

| Distance between two brackets | Recommended between 40~55mm |

| Installation screws | M4 |

| Traction Screw installation | M6 |

Detailed Introduction

Introduction to Wire-Pull Displacement Sensors

Wire-Pull Displacement Sensors are a sophisticated integration of linear displacement sensors in structure, which fully combines the advantages of angle displacement sensors, linear displacement sensors, and gear and bar transmissions. It is a compact, multi-purpose, simple to install, small installation space, no need to compensate for gaps, and has high-precision measurement, high repeatability measurement, high positioning accuracy, long stroke and life. It can be used for precise measurement and positioning control. With display instruments, it can also be used as a measuring instrument for manual measurement. This series of products has a large selection space, with three models of S/M/L, and the stroke ranges from 50MM to 11500MM. It has analog DC current 4-20MA, analog DC voltage 0-5V or 0-10V and pulse A, B, Z phase digital output to meet large stroke, high precision and various signal requirements. According to the actual use, all analog signal outputs can change the logic direction of the signal by switching the switch.

Installation precautions

1. Use the 4 fixing screw holes at the bottom of the mounting bracket to select the correct direction for direct installation according to the site and machine installation space facilities.

2. Pay attention to leaving enough buffer stroke at both ends during installation. During installation, pay attention to the horizontal angle of the traction cable, and try to make the cable slide horizontally and linearly from the outlet to the moving part mechanism during operation, and maintain the minimum angle (allowable deviation +/-30) to ensure measurement accuracy and cable life (see Figure 1). When installing vertically with a long stroke, it is recommended that the rope ruler body be installed at the bottom and the traction cable be pulled upward (see Figure 2).

3. The traction cable is a multi-strand stainless steel rope with a fluorine coating. Do not let it be cut, burned, hit, etc. by external forces. Excessive dust, debris or acidic and alkaline environment are enough to damage the internal measuring elements, resulting in poor operation, reduced measurement accuracy or even premature damage.

4. Before installing it on a workbench or fixed seat, do not pull out the steel cable with your hands or other objects and let it rebound instantly. This will cause the steel cable to break, damaging the main structure and personal safety.

5. The instantaneous acceleration of the traction movement of BWLS-S and BWLS-M series products should be ≤2m/s, and the absolute speed should be ≤1m/s; the instantaneous acceleration of the traction movement of BWLS-L series products should be ≤1.5m/s, and the absolute speed should be ≤0.75m/s; Exceeding the above speeds will reduce the reliability and service life of the product, and even cause the steel cable to break, please pay special attention.

6. If used in a non-linear motion mechanism, please install an appropriate pulley to convert the curved motion into linear motion (see Figures 3-1 and 3-2).

If used in harsh environments or special occasions, please install the protection mechanism yourself or contact our technical staff.

You might also like