Contact Us

- Building B, No. 17, Zijing Road, Pingxi, Pingdi Street, Longgang District, Shenzhen

- 934728633@qq.com

- +0755-29698036

Injection molding machine

Humanized sheet metal design and high rigidity frame design ensure the beauty and harmony of the machine. It adopts a high-performance plastic machine dedicated controller, which can be switched between Chinese and English, clear and intuitive, and easy to operate.

Detailed Introduction

Injection part

A short and powerful double-cylinder injection system is used to ensure smooth injection and no deformation of the fixed platen. The screw assembly is optimized to achieve better plasticizing capacity and plasticizing effect. The screw head and check ring are made of high-toughness material of hot-working tool steel imported from Japan. After special heat treatment, it has the characteristics of high temperature resistance, wear resistance, and heat erosion resistance. It still maintains high hardness under high temperature operation. The screw and material tube are made of high-grade alloy and direct ion nitriding treatment, which has the characteristics of high hardness, wear resistance, and wear resistance.

PID temperature control, combined with high-precision electronic ruler and controller, the speed and pressure of injection, pressure holding, sol, back pressure and other actions, ensure the quality of molded products and the continuity of production, automatic material cleaning, anti-casting, anti-cold start delay and other functions, ensure efficient, simple and safe work.

Clamping part

A new generation of curved hand clamping mechanism is adopted. Computer simulation optimizes the design of the crank parameters to make the moving plate move quickly and smoothly, combining the box-type moving plate, fixed plate and high-rigidity crank structure. Determine to achieve high strength and fatigue resistance. Compared with the same level of machines, it has a larger drawbar inner distance, mold capacity and mold opening stroke, and can process larger plastic products.

Hydraulic system

The high-efficiency energy-saving and high-precision proportional pressure flow variable pump system is adopted to match the output of the injection molding machine hydraulic system with the power required for the whole machine operation, without high-pressure throttling overflow energy loss. Compared with the quantitative pump, it saves 30%-60% of electricity. The motor of the same power can be equipped with a larger displacement oil pump, which speeds up the whole machine. At the same time, the low oil temperature prolongs the life of the seal.

Equipped with imported high-performance precision oil filter equipment, the normal service life of the hydraulic oil is longer, while ensuring the normal operation of the hydraulic system. In the mold opening and closing oil circuit, a buffer device is used to ensure that the mold opening and closing is smooth and impact-free. It is also equipped with a differential mold closing action, with high production efficiency.

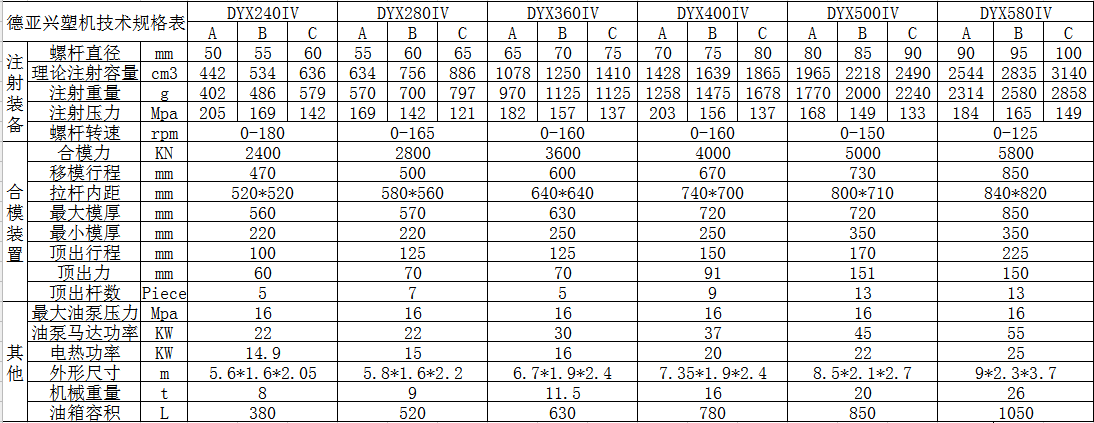

Technical parameters

You might also like